Proper axle installation and alignment are critical for maximizing speed and performance. Tools like the Pro Axle Guide ensure straight installation, while techniques like bending axles for rail riding setups can enhance stability. Regular maintenance and weight placement strategies further optimize results.

Pinewood Derby axles are a fundamental component of every race car, serving as the critical connection between the wheels and the car body. Typically made of metal, these small parts play a big role in determining speed and performance. Properly installed and aligned axles ensure smooth movement and stability, while poorly maintained ones can hinder a car’s potential. The stock axles provided in BSA kits are a good starting point, but with the right tools and techniques, they can be optimized for better results. Tools like the Pro Axle Guide help ensure precise installation, while strategies like bending axles for rail riding setups can enhance performance. Whether you’re a seasoned participant or a first-time builder, understanding how to prepare and maintain your axles is essential for achieving maximum speed and a competitive edge. This guide will walk you through the ins and outs of Pinewood Derby axles, helping you make informed decisions to build a faster, more efficient race car.

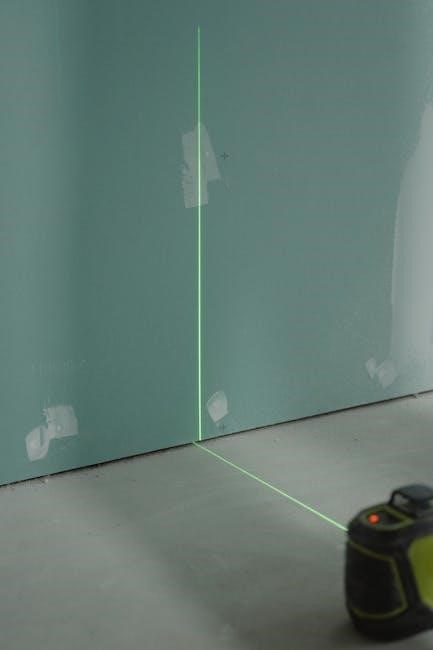

Tools for Installing Pinewood Derby Axles

Installing Pinewood Derby axles requires the right tools to ensure accuracy and precision. The Pro Axle Guide is a popular tool designed to help install axles straight into the axle slots, ensuring proper alignment and spacing. Another essential tool is the Pro Axle Inserter Guide, which simplifies the process of sliding axles into place while maintaining perfect straightness. Additionally, axle presses can be used to securely fasten the axles into the car body without causing damage. For finer adjustments, files and sandpaper are useful for smoothing out any rough edges or burrs on the axles, reducing friction and improving performance. A small chisel or hobby knife may also be needed to slightly enlarge axle slots for better fitment. While basic tools can suffice, specialized tools like the Pro Axle Guide offer enhanced precision, which can make a significant difference in achieving optimal results. Proper tool usage ensures that axles are installed correctly, minimizing issues during races and maximizing the car’s potential speed and stability.

Proper Axle Installation Techniques

Proper axle installation is crucial for ensuring your Pinewood Derby car performs optimally. Start by aligning the axles straight within the axle slots to maintain consistent wheel contact with the track. Use a tool like the Pro Axle Guide to ensure the axles are seated evenly and spaced correctly. Gently press the axles into place, avoiding excessive force that could bend or misalign them. For rail riding setups, bend the front axle slightly to ensure the car remains level and stable during races. After installation, spin each wheel to check for wobble or misalignment, addressing any issues before final assembly. Proper techniques ensure smooth operation, reduce friction, and maximize speed. Always test the car’s balance and alignment post-installation to guarantee peak performance on race day. These steps are essential for achieving the best results in your Pinewood Derby competition.

Preparing Stock BSA Axles for Racing

Prepping stock BSA axles can significantly enhance your Pinewood Derby car’s performance. Begin by inspecting each axle for any burrs or imperfections, as these can cause friction and reduce speed. Use a fine-grit sandpaper to gently polish the axles, ensuring they are smooth and free of debris. Next, straighten any bent axles by carefully aligning them with a tool or jig. Avoid over-bending, as this can weaken the axle’s structural integrity. For added lubrication, apply a small amount of high-performance oil or silicone-based spray to the axle heads. This step reduces friction between the wheels and axles, allowing the car to move more efficiently. Finally, test each axle by spinning the wheels to ensure they rotate smoothly and evenly. Proper preparation of the axles is a simple yet effective way to improve your car’s speed and overall performance on race day.

Aligning Axles for Maximum Speed

Proper axle alignment is essential for achieving maximum speed in a Pinewood Derby car. Misaligned axles can cause friction and uneven wheel rotation, slowing the car down. To ensure optimal alignment, start by inspecting the axle slots in the car body. Use a tool like the Pro Axle Guide to help install the axles straight and evenly. Once installed, spin each wheel to check for wobbling or uneven movement. If a wheel wobbles, gently bend the axle to correct the alignment. For precision, consider using a jig or alignment tool to fine-tune the axles. Additionally, ensure the car is level front to back to maintain consistent contact with the track. Properly aligned axles will reduce friction, improve stability, and allow the car to move smoothly down the track, maximizing its potential speed.

Bending Axles for Rail Riding Setups

Bending axles is a common technique used in rail riding setups to improve a Pinewood Derby car’s stability and speed. By slightly bending the axles, the car can maintain consistent contact with the track’s rail, reducing wobbling and friction. To bend the axles, start by removing the wheels and axles from the car body. Using a small tool like a screwdriver or an axle bender, gently bend the front axle downward and the rear axle upward. This creates a cant, ensuring the car stays level and travels smoothly along the track. For rail riding setups, the right front axle should point downward to guide the car along the rail. Be careful not to over-bend, as this can cause the wheels to misalign. Properly bent axles will enhance the car’s performance, allowing it to glide efficiently and maintain maximum speed throughout the race.

Weight Placement Strategies

Proper weight placement is crucial for optimizing the performance of a Pinewood Derby car. The goal is to maximize speed while ensuring the car remains stable and adheres to weight regulations. Placing weight toward the rear of the car is a common strategy, as it improves acceleration and reduces the likelihood of the front wheels lifting off the track. A flat weight positioned about 1 inch from the rear axle is a popular choice. When using this method, it’s important to chisel out a portion of the car body to securely fit the weight, ensuring it doesn’t interfere with the axles or wheels. Weight distribution should be carefully balanced to avoid overloading the rear, which can cause instability. Using materials like tungsten cubes or lead shot allows for precise weight placement and easy adjustment. Always ensure the car’s total weight does not exceed the maximum limit, typically 5 ounces. By strategically placing weight, you can enhance your car’s speed and competitiveness while maintaining compliance with race rules.

Maintenance Tips for Pinewood Derby Axles

Maintaining Pinewood Derby axles is essential to ensure optimal performance and longevity. Start by inspecting the axles for any debris or rust, which can hinder smooth rotation. Use a soft cloth or fine-grit sandpaper to clean and polish the axles, removing any imperfections that could cause friction. For stock BSA axles, lightly sanding the shafts can improve their alignment and reduce drag. After polishing, apply a small amount of dry lubricant, such as graphite powder, to the axle shafts to reduce friction further and enhance speed.

- Regularly check the axles for straightness and bend them slightly if necessary to ensure proper alignment.

- Store the axles in a protective case or bag to prevent damage or contamination when not in use.

- Avoid over-tightening the wheels on the axles, as this can create unnecessary friction and slow down the car.

By following these maintenance tips, you can keep your Pinewood Derby axles in top condition, ensuring your car performs at its best during races. Regular care and attention to detail will help maximize speed and reliability.

Troubleshooting Common Axle Issues

Common axle issues can significantly impact the performance of your Pinewood Derby car. One frequent problem is misaligned axles, which can cause the car to veer off the track. To fix this, use a Pro Axle Guide to ensure straight installation. Another issue is axles that are bent too much or too little, disrupting the car’s balance. Gently bending the axle to level the car front to back can resolve this. Wheel wobble is another concern, often caused by improper axle seating or debris on the axle shaft. Inspect and clean the axles, then reinstall the wheels securely. If axles are loose in the slots, apply a small amount of glue to hold them in place. For rail riding setups, ensure the bent axle aligns correctly with the track to avoid derailment. Addressing these issues promptly can restore your car’s speed and stability, ensuring optimal performance during races.

- Check axle alignment and straightness regularly.

- Use a Pro Axle Guide for precise installation.

- Clean axles and wheels to eliminate debris.

By identifying and fixing these common axle problems, you can keep your Pinewood Derby car running smoothly and competitively.

- Double-check axle alignment and straightness before races.

- Ensure all wheels spin freely and evenly.

- Verify weight distribution for maximum speed without losing control.

By following these guidelines and performing a thorough final check, you can ensure your Pinewood Derby car is race-ready and performs at its best. Good luck on the track!